ASP AUTOMOTIVE

a sophisticated product portfolio from the specialist

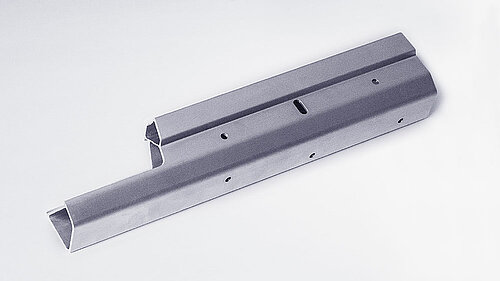

What sets our product portfolio apart from the rest? We are specialists in the segments we cover and have worked hard to earn an international reputation. For pipe and profile bent parts, for example, here at ASP AUTOMOTIVE we work with bending processes developed in-house and bending machines specially tailored to your needs. This means that we are in a position to guarantee our customers contours accurate down to a matter of tenths, even with complex bending processes.

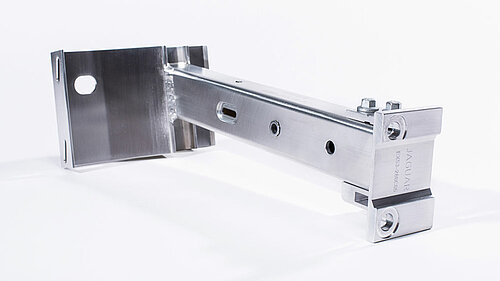

Precision is not only important in the automotive sector. It is a reality at every level of our product portfolio. Day after day. Because we know what we owe our customers and, as experts, we know the justified expectations. Of course, this also applies to our milling and turning parts, welded assemblies, pre-assemblies and also to aluminium alloys. Quality has a name: ASP AUTOMOTIVE!